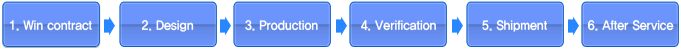

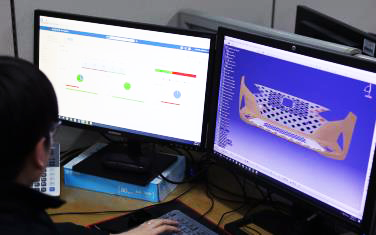

Integrated management of production flow process used to manage product information, drawing, spec, and other documents linked to the product. It is managed by the whole company minimizing error and time loss to focus on promote pre-production quality and fortification of technological competitiveness.

Effect

· Sharing of various information throughout the organization horizontally and vertically

· Able to monitor progress of work process

· Real time information delivery

· Related document and record keeping. History management by means of data base system

· Paperless work environment and save paper report creating time

· Prior quality issue prevented on following model vehicle by management of history and data base

· Easily confirm effectiveness

PDM driven program

PDM driven program

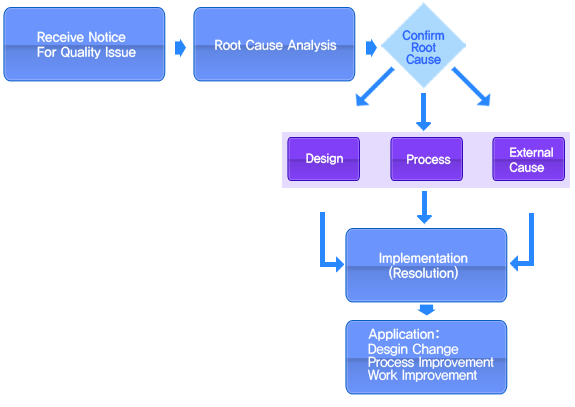

Tool used to systemize organizational structure/procedure/process as well as resources to assist in meeting quality targets.

Effect

· Gather scattered quality information and to share the information throughout the organization.

· Fast response on quality improvement.

· Overcome limitation of manual quality work.

· Precise feedback on quality improvement and process is able to be monitored.

· Prevent recurrence of quality issue.

· Prevent delay or omission of work process.

· Provide real time quality status.

· Provide real time information to suppliers and strengthen effectiveness of supplier improvement.

· Strengthen update on operation standard based on quality improvement and feedback system to prevent recurrence of quality issue