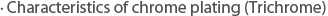

| Parameter | White Tri-ValentChrome | Dark Tri-ValentChrome | HexavalentChrome |

| Chrome Gloss | + | - | ++ |

| ChromeSpeed | + | - | - |

| Resistance to electric current | + | + | - |

| HES-Benefits | ++ | ++ | - |

| Resistance to contamination | + | + | ++ |

| CASS result | + | + | ++ |

| CaCl2 Result | ++ | + | - |

| Uniform electro depositionand covering ability | + | + | - |

| - Basic, + Good, ++ Superior | |||

-

Tri-valent process has replaced hexavalent processfor some tim- U.S and Canada has used this process for over 25 years.

Tri-valent process has replaced hexavalent processfor some tim- U.S and Canada has used this process for over 25 years. -

Higher performance compared to other type of chrome- Faster plating speed, uniform electrodeposition on low current

Higher performance compared to other type of chrome- Faster plating speed, uniform electrodeposition on low current -

Eco-friendly plating process!- Meet current and future environmental regulations

Eco-friendly plating process!- Meet current and future environmental regulations -

Satisfy both CaCl2 and CASS performance

Satisfy both CaCl2 and CASS performance -

Process to satisfy new color and design requests- When used with satin Ni process,

Process to satisfy new color and design requests- When used with satin Ni process,

it opens up various design capability.

- ·Since the Regulation such as ELV, WEEE regulate the release of hexavalent chrome, tri-valent chrome technology is the replacementfor hexavalent.

- ·Protection of worker from hazards

- ·Hexavalent has only one possible bright silver color, however tri-valent has variety of different color such as aesthetic gold to dark grey available adding variation to design aspect. When used with the satin nickel, the number of variation grow.

Superior covering power and uniform electro disposition.

Able to apply stable coat of chrome plate on complex design part

Able to create bright silver color of hexavalent chrome

High efficiency of current and fast plating speed

Metallic material furniture, hardware, etc

Mobile phone and home appliance

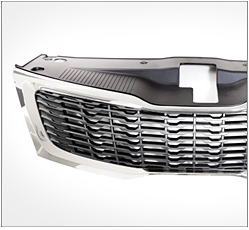

Exterior & interior automotive components

Chosen by OEM who prefer eco-friendly production

Constant and stable dark grey appearance

Reliable process control through management analysis of the additive

Superior performance on CaCl2 and CASS

Superior covering power and uniform electro disposition.

Mobile phone and automotive parts, etc

Open variety of design when used with satin nickel proces.